Unlock Your Potential: Why a Long Arm Sewing Machine is a Game-Changer for Your Business

In the demanding world of industrial production, where precision, durability, and scale are paramount, choosing the right equipment is crucial. While standard sewing machines have their place, industrial long arm sewing machines stand out as true powerhouses, designed to tackle projects that conventional machines simply can’t handle. These specialized machines offer an unparalleled combination of extended reach, robust construction, and advanced features, making them an indispensable asset for businesses aiming to elevate their production capabilities.

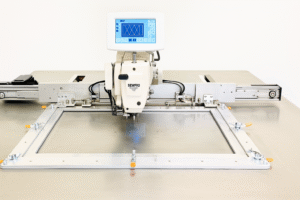

What Makes Long Arm Machines Unique?

The defining feature of a long arm sewing machine is its significantly extended “throat space” – the area between the needle and the machine’s body. This generous workspace, often ranging from 18 to 30 inches, allows for effortless maneuvering of large or bulky materials like upholstery, boat canvas, or multi-layered textiles without the need for constant folding or struggling. This design not only simplifies the sewing process but also helps maintain material integrity and stitch quality.

Beyond their impressive reach, long arm machines are built for heavy-duty performance. Constructed with durable metal components, they are designed to withstand continuous, demanding use in commercial environments. Equipped with powerful motors, they can effortlessly stitch through multiple layers of thick materials such as heavy leather, canvas, and dense webbing, ensuring consistent stitch quality even at high speeds.

Key Benefits for Your Business

Investing in a long arm sewing machine brings a multitude of advantages:

- Effortless Handling of Large Materials: The extended arm allows large projects to lie flat, reducing physical strain and making the sewing process smoother and more efficient.

- Increased Efficiency and Speed: Designed for high-speed operation, many models feature automatic functions like thread trimming, back-tacking, and foot lift, minimizing manual intervention and boosting productivity.

- Superior Stitch Quality: Robust construction and specialized feeding mechanisms ensure precise and consistent stitches, delivering professional-grade results crucial for high-quality products.

- Versatility: These machines can handle a wide range of fabrics, from lightweight to heavy-duty materials like denim, leather, and synthetics, making them suitable for diverse projects.

Where Long Arm Machines Excel

Long arm sewing machines are indispensable across various industries:

- Upholstery & Automotive Interiors: Ideal for large furniture pieces, car seats, and marine upholstery, allowing precise stitching on expansive panels.

- Tents, Awnings & Tarpaulins: Perfect for producing large outdoor gear from heavy canvas or waterproof materials, ensuring strong, durable seams.

- Leather Goods & Heavy Fabrics: Essential for bags, belts, and other leather products, as well as heavy-duty items like cargo slings, parachute straps, and sails.

Discover SEWPRO’s Long Arm Solutions

SEWPRO offers a range of high-quality long arm machines tailored to meet diverse industrial needs. Models like the SEWPRO 0617DL-18-7 provide an 18-inch long arm with full automation for upholstery and canvas. For even heavier tasks, the SEWPRO 733-30 boasts an impressive 30-inch long arm, capable of handling extremely thick materials and cords up to size 8 for critical applications like cargo slings. The SEWPRO 1508L-18H features an 18-inch long arm with an extra 2 inches of height, ideal for products that typically don’t fit standard machines. For double-needle heavy-duty work, the SEWPRO 8BL-20-2 offers a 20-inch long arm for canvas, vinyl, and leather.

Choosing the right long arm machine is a strategic investment that can significantly enhance your business’s efficiency, quality, and overall profitability.