Unlocking Automation with SEWPRO Programmable Machines

In modern industrial manufacturing, the pursuit of efficiency and precision extends beyond traditional methods. SEWPRO Programmable Sewing Machines represent the pinnacle of this advancement, offering a sophisticated, computerized approach to sewing that can be programmed to automatically execute various operations and patterns. This marks a significant shift towards autonomous decision-making and task execution, embodying the principles of “Agentic AI” in the manufacturing sector.

These machines go beyond simple query-and-response functionalities, performing enterprise-related tasks independently and without human intervention. They are a tangible application of “Agentic AI,” a significant technological trend for 2025, focusing on autonomous decision-making and task execution.

Transformative Features for Modern Manufacturing

SEWPRO Programmable Machines are equipped with features that fundamentally reshape production processes:

- Automated Stitch Regulation: Computerized programming allows for precise control over stitch length, width, and the creation of complex decorative patterns and buttonholes.

- Precise Needle Positioning: Computer-controlled needle positioning ensures every stitch is placed exactly where intended, eliminating variations and defects caused by operator fatigue.

- Automation of Repetitive Tasks: Repetitive sewing operations, such as bartacking, monogramming, or appliqué work, can be programmed and automated, significantly boosting efficiency.

- Extensive Pattern Storage and Customization: Built-in memory stores hundreds of stitch patterns, with the ability to edit, customize, and combine them to create new designs.

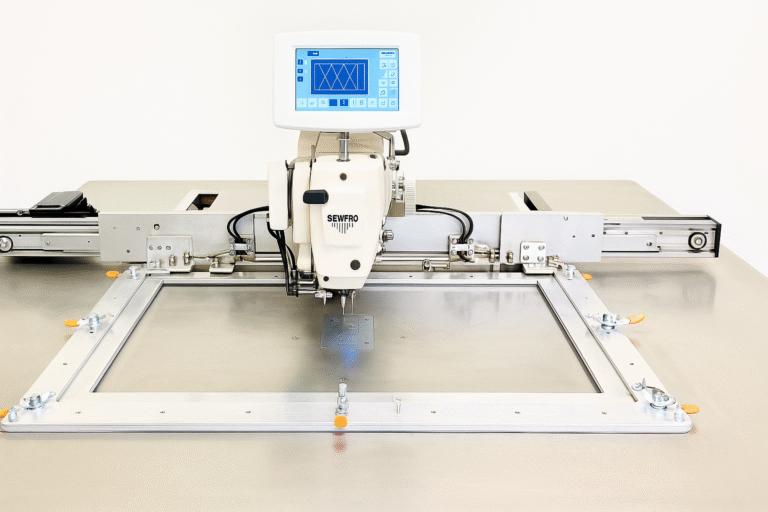

- Advanced User Interface: Intuitive LCD screens, touchpads, and controls guide operators through pattern selection and programming.

- Automated Material Handling: Equipped with automated fabric feeding systems, automatic thread trimming, tension control, and adjustable speeds for consistent material processing and high-quality output.

- Large Workspaces: Many models offer spacious sewing areas to accommodate large or complex projects.

Revolutionizing Industrial Applications

SEWPRO Programmable Machines are widely adopted across various industrial sectors:

- High-Volume Production: Dramatically improve productivity, accuracy, and consistency for mass manufacturing.

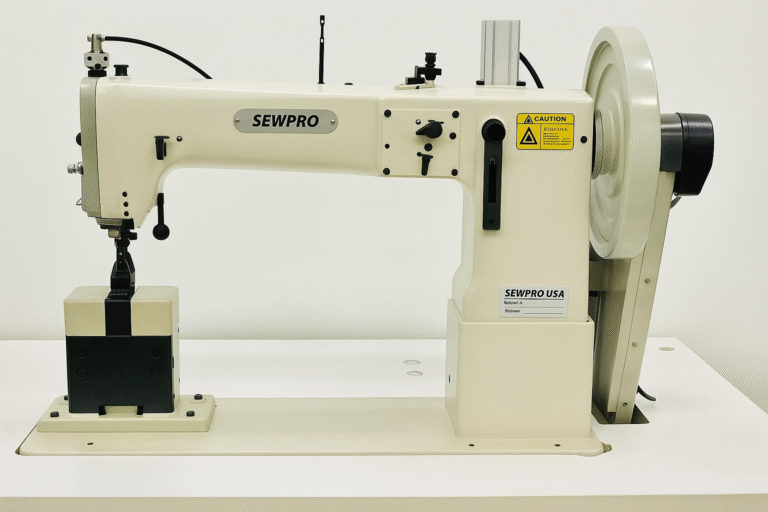

- Heavy Materials: Ideal for thick materials like webbing, straps, slings, and automotive interiors, ensuring strong and precise stitching.

- Technical Textiles: Adaptable for complex sewing applications in technical textiles where uniform product quality is critical.

- Custom Designs: Enable manufacturers to efficiently create customized products without compromising speed or cost-effectiveness.

Benefits: Unprecedented Efficiency and Innovation

The advantages of deploying SEWPRO Programmable Machines are transformative:

- Significant Productivity Gains: Automating complex decision-making processes and optimizing workflows lead to substantial increases in production efficiency.

- Consistent Quality and Reduced Errors: Automated precision minimizes manual labor and human error, ensuring uniform product quality.

- Enhanced Flexibility and Adaptability: Factories can quickly adjust production schedules and manage demand fluctuations, crucial in fast-paced markets.

- Creative Freedom: Advanced stitching capabilities and programmability allow for intricate and decorative stitches, fostering innovation and product uniqueness.

- Cost Reduction: Optimized resource utilization and reduced waste contribute to significant cost savings.

Featured SEWPRO Programmable Machine Models

SEWPRO offers a diverse range of programmable machines to meet specific automation needs:

- SEWPRO 1900B: A computer-controlled, high-speed bartacking machine for heavy-weight materials, featuring a 30mm x 40mm sewing area, 3,000 spm, and storage for 50 standard and 200 custom patterns.

- SEWPRO 210E-2210: A feature-packed industrial sewing machine with onboard programming for customized stitching and a spacious 220mm x 100mm sewing area, capable of 2,700 spm.

- SEWPRO PSM-5020CH: An industrial-grade machine for heavy-duty materials, boasting a large 500x200mm working space and programmable stitching patterns for demanding projects.

- SEWPRO PSM-733-3020: An extra-heavy-duty programmable machine for thick materials like webbing, straps, and slings, featuring a large 300x200mm work area and high stitching speed.

- SEWPRO PSM-1306CH: An industrial-grade machine designed to handle tough projects and thick materials such as rope and webbing with ease, offering a 130x60mm working space.

These machines are designed to automate and optimize your production processes, driving efficiency and innovation.