Introduction

In industries where leather, webbing, and vinyl are cut into precise straps, efficiency and accuracy are non-negotiable. SEWPRO strap cutting machines are designed to help manufacturers save time, reduce material waste, and achieve consistent, professional results. Whether you produce belts, bags, harnesses, or industrial strapping, SEWPRO delivers cutting solutions that keep your production line running smoothly.

Why Choose a Strap Cutting Machine?

Cutting straps manually can lead to inconsistent widths, wasted material, and higher labor costs. A strap cutting machine automates the process, ensuring that every strap is perfectly uniform. This consistency improves both product quality and production speed, ultimately boosting profitability.

Key Benefits of SEWPRO Strap Cutting Machines

- Precision Cutting – Achieve perfect strap widths, from narrow bindings to wide belts.

- Versatility – Handle leather, vinyl, webbing, nylon, and other heavy-duty materials.

- Time Savings – Cut hundreds of straps in a fraction of the time it takes manually.

- Durability – Built with industrial-grade components for long service life.

- Ease of Use – Simple controls and adjustable settings make operation effortless.

Applications Across Industries

- Leather Goods – Belts, bag straps, wallet straps

- Automotive & Marine – Upholstery binding, safety straps

- Outdoor & Sporting Goods – Backpack straps, sports gear

- Industrial Applications – Cargo slings, tie-down straps, lifting harnesses

- Equestrian & Saddlery – Bridles, reins, harness straps

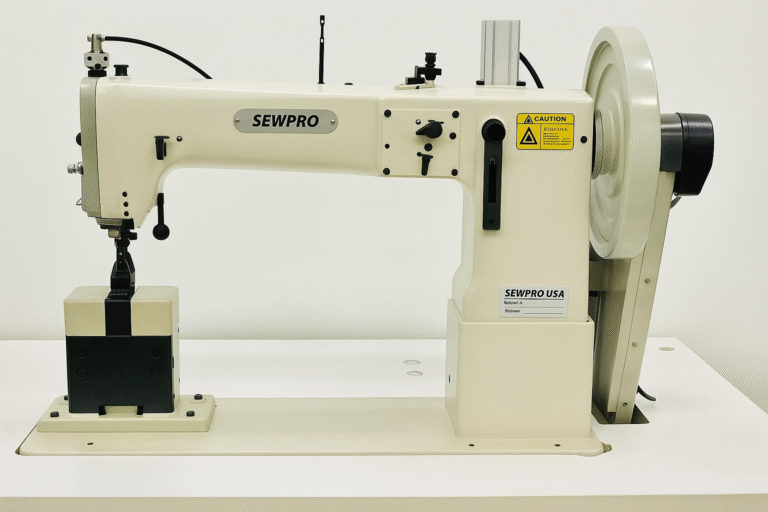

Featured SEWPRO Strap Cutting Machine: LEATHERPRO 4

The LEATHERPRO Model 4 is the professional’s choice for cutting leather, vinyl, and similar materials into perfectly sized straps. Key specifications include:

- Cutting range: 1/16″ up to 3 ¾” wide

- Maximum thickness: ¼”

- Built-in 110V gear reduction motor

- Foot pedal control for precise speed adjustment

- Reverse rotation for easy material handling

This portable yet powerful model is ideal for small workshops and high-volume factories alike.

How Strap Cutting Machines Improve Production Efficiency

By incorporating a SEWPRO strap cutting machine into your workflow, you can significantly reduce labor time and improve output consistency. Operators can prepare strap materials in bulk, feeding multiple production lines at once. This streamlined process helps manufacturers meet tight deadlines without compromising quality.

For an in-depth guide on industrial strap cutting, see Manufacturing Today – Material Processing Innovations.

Maintenance Tips for Long-Term Performance

- Keep blades sharp and clean for precise cuts.

- Regularly inspect rollers and feeding mechanisms.

- Lubricate moving parts as specified in the manual.

- Store the machine in a dry, dust-free environment.

Proper maintenance ensures your strap cutting machine remains reliable for years.

Why SEWPRO?

SEWPRO combines industrial engineering with user-friendly design. Our strap cutting machines are tested for performance and built to handle continuous production. From small leather workshops to large-scale industrial plants, SEWPRO provides cutting solutions tailored to your needs.

In industries requiring the consistent production of straps, belts, or webbing, manual cutting methods are often slow, inconsistent, and labor-intensive. SEWPRO Strap Cutting Machines provide a specialized, high-efficiency solution, ensuring precise and rapid material processing that significantly enhances productivity and reduces waste.

SEWPRO Strap Cutting Machines are purpose-built for accurately and quickly transforming various materials into uniform strips. They are designed to deliver clean, precise cuts, which is crucial for maintaining quality standards throughout the production process.

Key Features for Optimized Material Processing

SEWPRO Strap Cutting Machines incorporate features that make them indispensable for high-volume and precision cutting tasks:

- Precision Blades: Equipped with sharp, durable blades that ensure clean and accurate cuts of strap material.

- High Efficiency: Designed to cut through straps quickly, saving significant time and effort compared to manual methods.

- Material Versatility: Capable of cutting a wide range of materials, including leather, vinyl, rubber, and cardboard.

- Customizable Widths: Many models come with various spacers and knives, allowing for the production of multiple strips with customizable widths in a single pass.

- Open-Ended Design: Certain models, like the SEWPRO AK-20, feature an open-ended design that accommodates extra-wide materials without pre-cutting.

- Automated Control: Some machines include features like built-in motors, reverse rotation, and foot pedal control for smooth and precise operation.

Ideal Applications for Enhanced Throughput

SEWPRO Strap Cutting Machines are vital in sectors where consistent strap production is a core requirement:

- Leather Goods Manufacturing: Essential for creating leather belts, horse bridles, leather laces, and other accessories.

- Bag and Luggage Production: Used to cut straps for handles, closures, and decorative elements.

- Automotive and Marine Industries: For producing tie-down straps, webbing, and other components requiring precise, durable strips.

- Crafting and Upholstery: Streamlines the preparation of materials for various crafting projects and upholstery work.

- Industrial Packaging: Automated strapping systems, which often integrate cutting functions, significantly enhance efficiency in warehouses and manufacturing plants by quickly securing products.

Benefits: Productivity, Consistency, and Cost Savings

Implementing SEWPRO Strap Cutting Machines offers substantial benefits for businesses:

- Enhanced Efficiency and Productivity: Automate and accelerate the cutting process, significantly reducing production time and increasing throughput.

- Improved Consistency: Ensures uniform strap dimensions and quality, leading to more professional finished products and reduced material waste.

- Lower Labor Costs and Safety: Reduces the need for manual labor and minimizes physical strain and safety hazards associated with hand cutting.

- Cost-Effectiveness: Long-term savings on material and labor, despite initial investment, make these machines highly cost-competitive.

Featured SEWPRO Strap Cutting Machine Models

SEWPRO offers robust strap cutting solutions designed for industrial demands:

- LEATHERPRO 4: A powerful and portable machine for cutting leather, vinyl, and similar materials into perfectly sized straps. It can cut widths from 1/16″ to 3 3/4″ and materials up to 1/4″ thick, featuring a built-in 110V motor and foot pedal control.

- SEWPRO AK-20: An industrial-grade strap-cutting machine known for precision and speed. It offers a 14-inch cutting width, an open-ended design for extra-wide materials, and can cut up to 3/8 inch thick, coming with various spacers and 8 knives for customization.

These machines are engineered to bring precision and speed to your material preparation.