Introduction

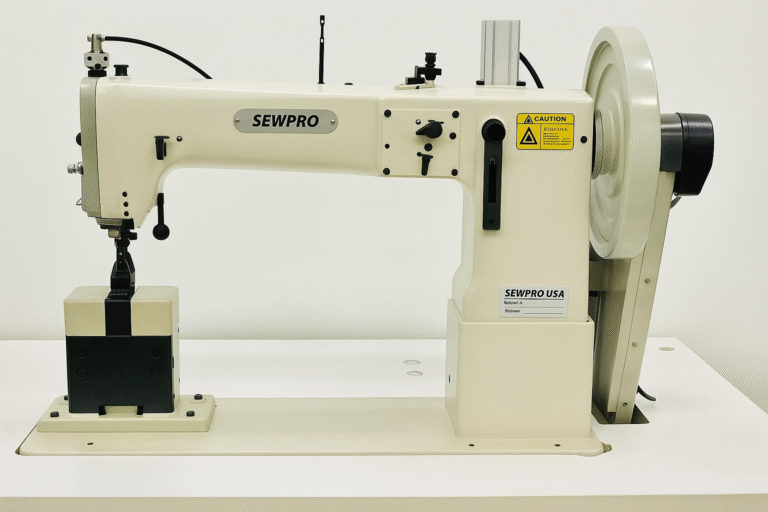

When it comes to sewing complex, three-dimensional products with precision and control, post bed sewing machines stand in a league of their own. SEWPRO’s range of post bed machines is engineered for manufacturers who demand accuracy, versatility, and durability in every stitch. From leather boots to luxury handbags, these machines handle the most challenging sewing tasks with ease.

What is a Post Bed Sewing Machine?

Unlike flat bed or cylinder bed machines, post bed sewing machines feature a raised vertical column — the “post” — that elevates the sewing area above the base. This design offers unmatched access to tight spaces, making it perfect for tubular, curved, or layered products.

The post bed sewing machine is an essential tool in industries such as leather goods, footwear manufacturing, and upholstery production, where accuracy and control are paramount.

Key Advantages of SEWPRO Post Bed Sewing Machines

- Exceptional Access & Visibility – The elevated post allows easy maneuvering around curves and complex seams.

- Perfect for Leather & Upholstery – Consistent stitches even in thick or layered materials.

- Advanced Feeding Systems – Triple feed or walking foot to prevent slippage.

- Ideal for Decorative Stitching – Great for topstitching, binding, and finishing.

Applications Across Industries

- Footwear – Boot tops, shoe uppers, sports footwear

- Leather Goods – Handbags, belts, wallets

- Upholstery – Furniture, automotive, marine seating

- Bags & Luggage – Backpacks, travel gear

- Outdoor Equipment – Canvas covers, tarps, sports gear

Featured SEWPRO Post Bed Machine Models

SEWPRO offers a selection of high-performance Post Bed Machines tailored for specific industrial needs:

- SEWPRO 243H-P2: An extra heavy-duty, double-needle machine with triple feed and a large barrel shuttle, ideal for thick threads and materials like car upholstery, furniture, and luggage. It offers a max speed of 600 spm and a max stitch length of 12mm.

- SEWPRO 1710D: A single-needle, triple unison feed lockstitch machine with a large vertical axis rotary hook. Designed for medium to medium-heavy fabrics, leather, canvas, and vinyl, perfect for car upholstery, handbags, and luggage.

- SEWPRO 1760: A heavy-duty, double-needle industrial sewing machine specifically for upholstery, leather, and canvas, available with 8-12mm needle gauges.

These machines are designed to bring precision and efficiency to your most demanding projects.

How Post Bed Sewing Machines Improve Manufacturing Efficiency

Integrating post bed sewing machines into production boosts output and quality. Operators can work faster on intricate products without constant repositioning, reducing rejects and improving consistency. This is critical for businesses producing high-end leather goods, where precision determines brand reputation.

Choosing the Right SEWPRO Post Bed Sewing Machine

When choosing a post bed sewing machine, consider:

- Material type and thickness

- Thread size and strength

- Production volume and speed requirements

- Special features like automatic back-tack or thread trimming

For guidance, see Sewing Machine Industry Guide – Textile World or contact SEWPRO for tailored recommendations.

Maintenance Tips for Long-Term Performance

- Keep the bobbin area clean and lint-free.

- Oil moving parts as per the user manual.

- Check feed mechanisms for wear.

- Use the correct needle and thread for your material.

Conclusion

If your work demands precision, control, and durability, SEWPRO post bed sewing machines deliver unmatched performance. From leather boots to luxury upholstery, these machines are built to meet industrial standards while maintaining fine craftsmanship.